·The main oil cylinders on both sides have broken through the traditional stroke control method of mechanical stop block bending machines. Instead, they adopt a closed-loop control method composed of German imported electro-hydraulic synchronous valves and imported grating rulers. The position feedback accuracy of the slider is high, the operation is accurate and stable, the synchronization performance is good, and the bending accuracy and the repeat positioning accuracy of the slider are high.

·The hydraulic systems all adopt the integrated control system imported from Germany, which reduces the installation of pipelines, ensures the working stability of the machine tool, and has a simple and beautiful appearance.

For machine prices and efficient production solutions, please contact us!

Inquiry

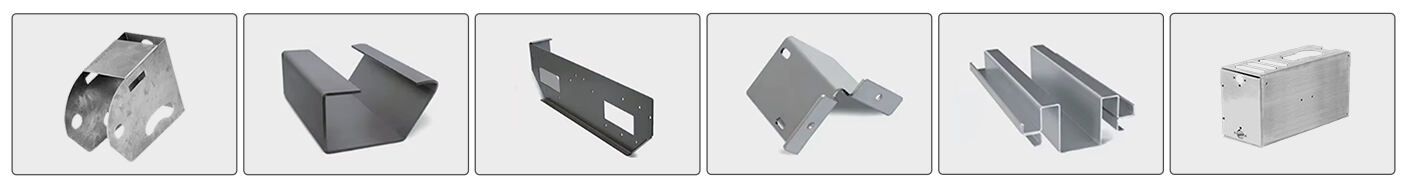

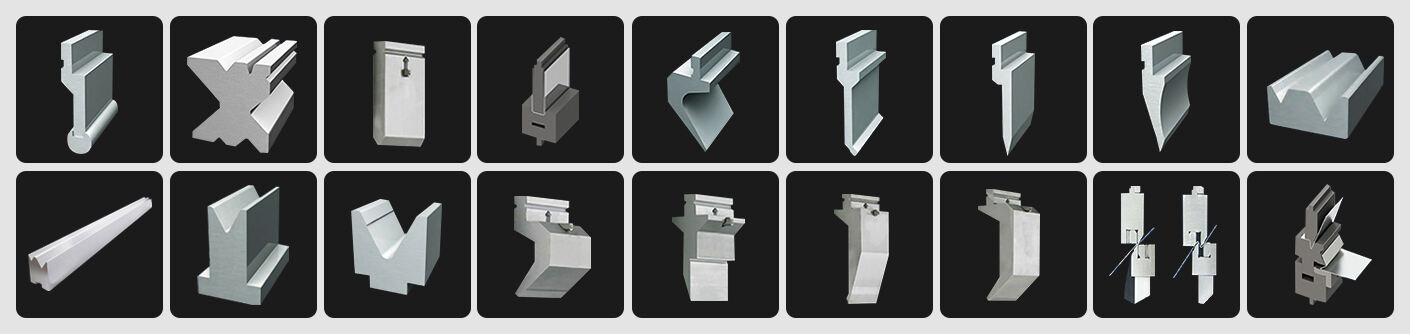

A variety of mold options are available to match various bending workpieces, ensuring higher precision.

|

No |

Configuration |

Numerical value |

unit |

Remark |

|

1 |

Nominal pressure |

1350 |

KN |

|

|

2 |

Foldable plate width |

3200 |

mm |

|

|

3 |

Slide stroke |

200 |

mm |

|

|

4 |

Maximum opening height |

420 |

mm |

|

|

5 |

Column spacing |

2700 |

mm |

|

|

6 |

throat depth |

400 |

mm |

|

|

7 |

Fast down speed |

160 |

mm/s |

|

|

8 |

Return speed |

130 |

mm/s |

|

|

9 |

Working speed |

10 |

mm/s |

|

|

10 |

Main motor power |

11 |

Kw |

servo motor |

|

11 |

CNC system |

DA53T |

|

Netherlands |

|

12 |

X-axis travel of rear stopper |

500 |

mm |