Tube laser cutting represents one of the most advanced manufacturing technologies available today, revolutionizing how industries process hollow materials across sectors ranging from automotive to construction. This sophisticated manufacturing process utilizes high-powered laser beams to precisely cut, shape, and perforate tubular materials with exceptional accuracy and speed. Unlike traditional cutting methods that often require multiple setups and tools, tube laser cutting delivers superior precision while maintaining consistent quality across complex geometries and intricate designs.

Modern manufacturing demands increasingly complex components with tighter tolerances, making traditional cutting methods insufficient for many applications. The integration of laser technology with advanced automation systems has created opportunities for manufacturers to produce intricate tube components that were previously impossible or economically unfeasible. This technology has become indispensable in industries where precision, speed, and material efficiency are paramount considerations for competitive advantage.

Understanding Tube Laser Cutting Technology

Core Principles of Laser Cutting Process

The fundamental principle behind tube laser cutting involves focusing a high-intensity laser beam onto the material surface, creating localized heating that vaporizes or melts the material along predetermined cutting paths. This process occurs within milliseconds, allowing for extremely precise cuts with minimal heat-affected zones. The laser beam is typically generated using fiber optic technology, which provides superior beam quality and energy efficiency compared to older CO2 laser systems.

Fiber lasers used in tube laser cutting operate at wavelengths around 1070 nanometers, which are readily absorbed by most metals including steel, stainless steel, aluminum, and copper alloys. The focused beam diameter can be as small as 0.1 millimeters, enabling intricate detail work and tight tolerances that mechanical cutting methods cannot achieve. Advanced beam shaping technology allows operators to optimize cutting parameters for different material types and thicknesses.

Material Interaction and Heat Management

During the tube laser cutting process, the interaction between the laser beam and target material creates a controlled melting or vaporization zone. Assist gases such as oxygen, nitrogen, or compressed air are introduced to facilitate the cutting process and remove molten material from the kerf. The choice of assist gas significantly influences cut quality, edge finish, and processing speed for different material compositions.

Heat management becomes critical in tube laser cutting applications where material properties must be preserved outside the immediate cutting zone. Advanced cooling systems and optimized cutting parameters ensure that thermal distortion remains minimal, maintaining dimensional accuracy throughout the manufacturing process. This precise heat control enables the processing of heat-sensitive materials and thin-walled tubes without compromising structural integrity.

Advanced Machine Components and Systems

Laser Generation and Delivery Systems

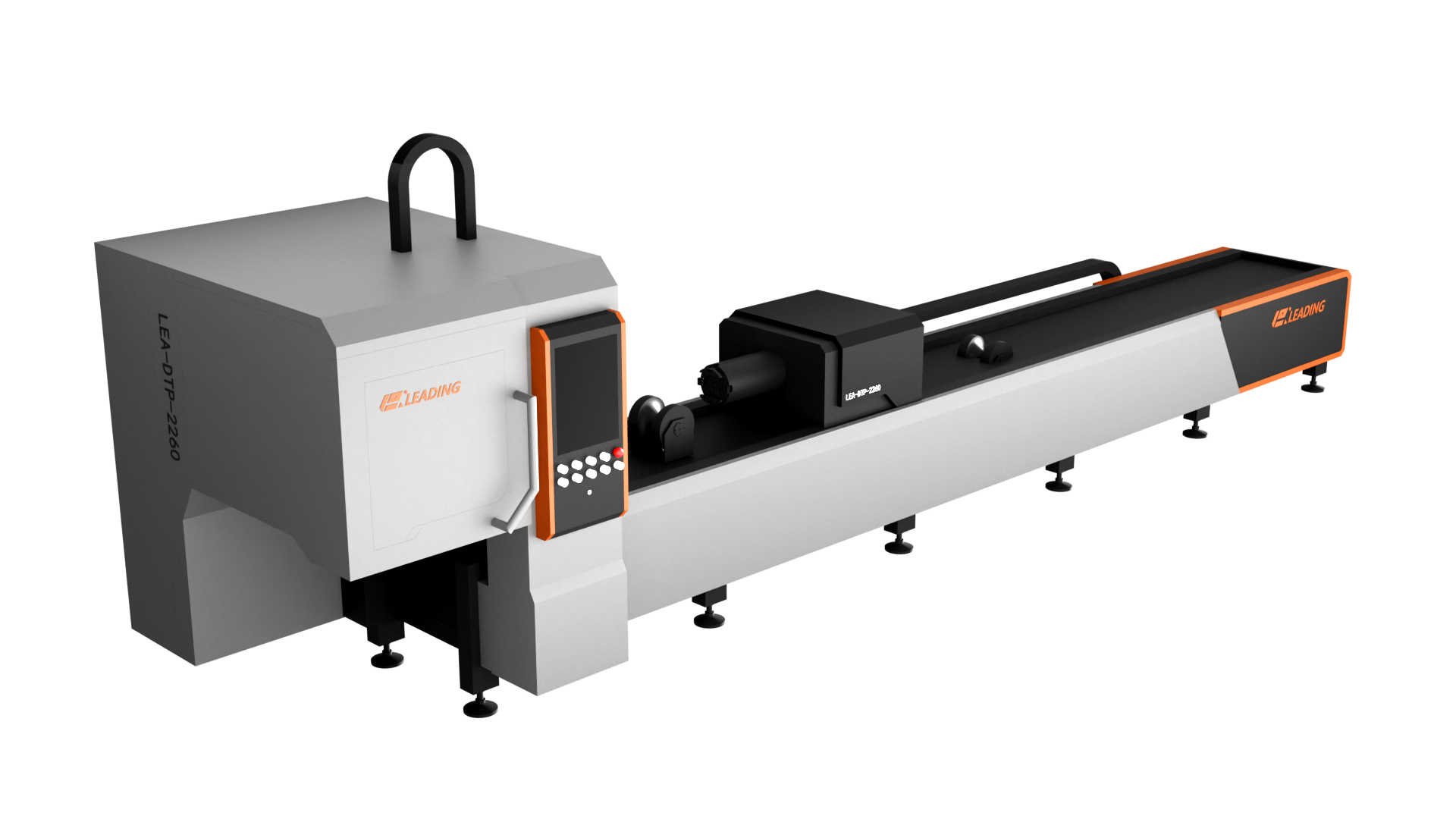

Modern tube laser cutting machines incorporate sophisticated fiber laser generators capable of producing power levels ranging from 1000 watts to over 15000 watts, depending on application requirements. These laser sources utilize semiconductor diode pumping technology to achieve exceptional electrical efficiency and beam quality. The laser energy is transmitted through flexible fiber optic cables to cutting heads equipped with precision focusing optics.

The cutting head assembly represents a critical component in tube laser cutting systems, incorporating dynamic focus adjustment, assist gas delivery, and protective sensing systems. Advanced cutting heads can automatically adjust focal position and beam diameter during operation, optimizing cutting parameters for varying material thicknesses and geometries. Protective systems monitor for potential collisions and contamination that could damage expensive optical components.

Automation and Material Handling

Sophisticated automation systems distinguish professional tube laser cutting equipment from basic cutting tools. Automated loading and unloading systems can handle tubes ranging from small diameter pipes to large structural sections, reducing operator intervention and improving production consistency. These systems often incorporate robotic arms, conveyor systems, and automatic sorting mechanisms for finished components.

Chuck and tailstock systems provide precise tube positioning and rotation during cutting operations, enabling complex multi-axis cuts and intricate patterns. Advanced machines feature servo-controlled rotation with position feedback systems that maintain accuracy within micrometers. This precision positioning capability allows tube laser cutting systems to produce components with complex geometries including slots, holes, notches, and beveled edges in single setups.

Applications Across Manufacturing Industries

Automotive and Transportation Sector

The automotive industry represents one of the largest markets for tube laser cutting technology, utilizing these systems to manufacture exhaust systems, chassis components, roll cages, and structural elements. Modern vehicles incorporate increasingly complex tube assemblies that require precise fitment and consistent quality standards. Tube laser cutting enables manufacturers to produce lightweight components with optimized strength-to-weight ratios essential for fuel efficiency improvements.

Advanced automotive applications include processing of high-strength steel tubes for safety structures, aluminum extrusions for electric vehicle battery enclosures, and stainless steel components for emission control systems. The ability to create complex joint geometries and precise hole patterns in single operations significantly reduces assembly time and improves manufacturing efficiency. Quality standards in automotive manufacturing demand exceptional consistency that tube laser cutting readily provides.

Construction and Architectural Applications

Construction industries utilize tube laser cutting for producing structural steel components, architectural features, and specialized building systems. Complex building designs increasingly incorporate curved and angular tube assemblies that require precise cutting and fitting. Traditional fabrication methods often struggle with the geometric complexity demanded by modern architectural projects, making tube laser cutting an essential technology for competitive contractors.

Architectural applications include decorative screens, structural glazing systems, handrail assemblies, and custom building facades. The precision achievable through tube laser cutting eliminates the need for extensive field modifications and ensures proper fit-up during construction. This accuracy reduces installation time and labor costs while improving overall project quality and client satisfaction.

Process Advantages and Technical Benefits

Precision and Quality Characteristics

Tube laser cutting delivers exceptional dimensional accuracy with typical tolerances ranging from ±0.05mm to ±0.15mm depending on material type and thickness. This precision level enables the production of components that fit together perfectly without additional machining or adjustment operations. The laser cutting process produces smooth, oxide-free edges on most materials, eliminating secondary finishing operations in many applications.

Edge quality achieved through tube laser cutting surpasses most alternative cutting methods, with minimal heat-affected zones and virtually no burr formation. The narrow kerf width, typically 0.1mm to 0.3mm, minimizes material waste while maintaining precise dimensional control. This combination of accuracy and quality makes tube laser cutting particularly valuable for applications requiring close tolerances and superior surface finish.

Production Efficiency and Flexibility

Modern tube laser cutting systems offer remarkable production flexibility, capable of processing diverse tube shapes including round, square, rectangular, oval, and custom profiles. Quick changeover between different tube sizes and shapes minimizes setup time, enabling efficient production of small batches and prototype components. Advanced programming software allows operators to optimize cutting sequences and reduce cycle times automatically.

The non-contact nature of tube laser cutting eliminates tool wear and reduces maintenance requirements compared to mechanical cutting methods. Laser systems can operate continuously for extended periods with minimal intervention, improving overall equipment effectiveness and production capacity. Integration with manufacturing execution systems enables real-time monitoring and quality control throughout the production process.

Material Considerations and Capabilities

Metal Types and Thickness Ranges

Tube laser cutting systems can process virtually all metallic materials commonly used in manufacturing, including carbon steel, stainless steel, aluminum, copper, brass, and exotic alloys. Wall thickness capabilities typically range from 0.5mm for thin-walled applications up to 25mm for heavy structural components, depending on laser power and material properties. Different materials require optimized cutting parameters to achieve optimal results.

Carbon steel represents the most common material processed through tube laser cutting, offering excellent cutting speeds and edge quality with oxygen assist gas. Stainless steel applications often utilize nitrogen assist gas to prevent oxidation and maintain corrosion resistance properties. Aluminum and copper alloys require higher laser power densities due to their thermal conductivity and reflectivity characteristics, but produce excellent results when properly processed.

Geometric Complexity and Design Limitations

The geometric capabilities of tube laser cutting systems continue to expand with advancing technology, enabling the production of increasingly complex components. Modern systems can create intricate patterns, overlapping holes, beveled edges, and complex joint preparations in single operations. Multi-axis cutting heads allow for angled cuts and compound angles that would be impossible with conventional cutting methods.

Design limitations primarily relate to material thickness, tube diameter, and geometric accessibility rather than cutting precision. Very small internal features may be limited by laser beam diameter and focusing capabilities, while extremely thick materials may require multiple passes or alternative processing methods. Understanding these limitations helps designers optimize components for efficient tube laser cutting production.

Programming and Operational Considerations

CAD Integration and Nesting Software

Modern tube laser cutting systems integrate seamlessly with computer-aided design software, enabling direct import of 3D models and automatic generation of cutting programs. Advanced nesting software optimizes material utilization by arranging multiple components along tube lengths to minimize waste. These programs consider material properties, cutting parameters, and machine capabilities to generate efficient production sequences automatically.

Simulation capabilities allow operators to verify cutting programs before production, identifying potential issues such as collisions, material interference, or suboptimal cutting sequences. Real-time process monitoring provides feedback on cutting quality and enables automatic parameter adjustment during production. This integration of design, programming, and production systems significantly reduces setup time and improves manufacturing efficiency.

Operator Skills and Training Requirements

Successful tube laser cutting operations require skilled operators who understand laser physics, material properties, and manufacturing processes. Training programs typically cover safety procedures, machine operation, programming basics, and quality control methods. Advanced operators develop expertise in optimizing cutting parameters for different materials and applications, maximizing productivity and quality outcomes.

Safety considerations are paramount in tube laser cutting operations, requiring proper training in laser safety protocols, material handling procedures, and emergency response systems. Operators must understand the importance of proper ventilation, eye protection, and fire prevention measures. Ongoing training ensures operators stay current with evolving technology and best practices in tube laser cutting applications.

Future Developments and Industry Trends

Emerging Technologies and Innovations

The future of tube laser cutting technology focuses on increased automation, artificial intelligence integration, and enhanced processing capabilities. Machine learning algorithms are being developed to optimize cutting parameters automatically based on material feedback and quality measurements. Predictive maintenance systems will reduce downtime and improve overall equipment effectiveness through advanced sensor monitoring and data analytics.

Emerging laser technologies promise even higher power levels, improved beam quality, and enhanced processing speeds for tube laser cutting applications. Ultrashort pulse lasers are being investigated for processing challenging materials and achieving superior edge quality with minimal heat input. Integration with additive manufacturing technologies may enable hybrid processing systems that combine cutting and material deposition capabilities.

Market Growth and Industry Adoption

Growing demand for lightweight, high-strength components across multiple industries continues driving adoption of tube laser cutting technology. Electric vehicle manufacturing, renewable energy systems, and advanced aerospace applications create new opportunities for specialized tube processing capabilities. Market expansion in developing regions provides additional growth potential for tube laser cutting equipment manufacturers and service providers.

Industry consolidation and technology standardization are improving equipment compatibility and reducing training requirements across different machine platforms. Collaborative robot integration and Industry 4.0 connectivity enable tube laser cutting systems to operate within larger automated manufacturing environments. These trends suggest continued growth and technological advancement in tube laser cutting applications across diverse manufacturing sectors.

FAQ

What materials can be processed using tube laser cutting technology

Tube laser cutting systems can process virtually all metallic materials including carbon steel, stainless steel, aluminum, copper, brass, titanium, and various specialty alloys. Wall thickness capabilities typically range from 0.5mm to 25mm depending on laser power and material properties. Different materials require optimized cutting parameters including laser power, cutting speed, and assist gas selection to achieve optimal results. Non-metallic materials such as plastics and composites can also be processed with appropriate laser wavelengths and parameter settings.

How does tube laser cutting compare to traditional cutting methods in terms of accuracy

Tube laser cutting delivers exceptional dimensional accuracy with typical tolerances of ±0.05mm to ±0.15mm, significantly superior to mechanical cutting methods such as sawing or plasma cutting. The laser process produces smooth, burr-free edges with minimal heat-affected zones, eliminating secondary finishing operations in most applications. Traditional methods often require additional machining steps to achieve comparable accuracy and surface finish quality, making tube laser cutting more efficient for precision applications.

What are the main advantages of automated tube laser cutting systems

Automated tube laser cutting systems provide numerous advantages including consistent quality, reduced operator intervention, improved safety, and higher production rates. Automated loading and unloading systems minimize material handling time while reducing the risk of operator injury. Advanced programming capabilities enable complex cutting sequences with automatic parameter optimization, ensuring consistent results across production runs. Integration with manufacturing execution systems provides real-time monitoring and quality control throughout the manufacturing process.

How do assist gases affect the tube laser cutting process and quality

Assist gases play a crucial role in tube laser cutting by facilitating material removal, protecting cutting optics, and influencing edge quality characteristics. Oxygen assist gas provides faster cutting speeds for carbon steel while creating a slightly oxidized edge finish. Nitrogen assist gas prevents oxidation and produces superior edge quality for stainless steel and aluminum applications. Compressed air offers an economical option for general-purpose cutting while argon provides optimal results for specialized materials such as titanium and reactive alloys.