Manufacturing industries across the globe are experiencing a technological revolution that demands precision, efficiency, and cost-effectiveness in metal fabrication processes. Among the various cutting technologies available today, tube laser cutting has emerged as a transformative solution that addresses the complex requirements of modern manufacturing. This advanced cutting method combines the precision of laser technology with specialized equipment designed specifically for tubular materials, offering manufacturers unprecedented capabilities in processing pipes, tubes, and hollow sections. Understanding when to implement tube laser cutting technology can significantly impact production efficiency, product quality, and overall manufacturing competitiveness in today's demanding industrial landscape.

Understanding Tube Laser Cutting Technology

Core Principles and Mechanisms

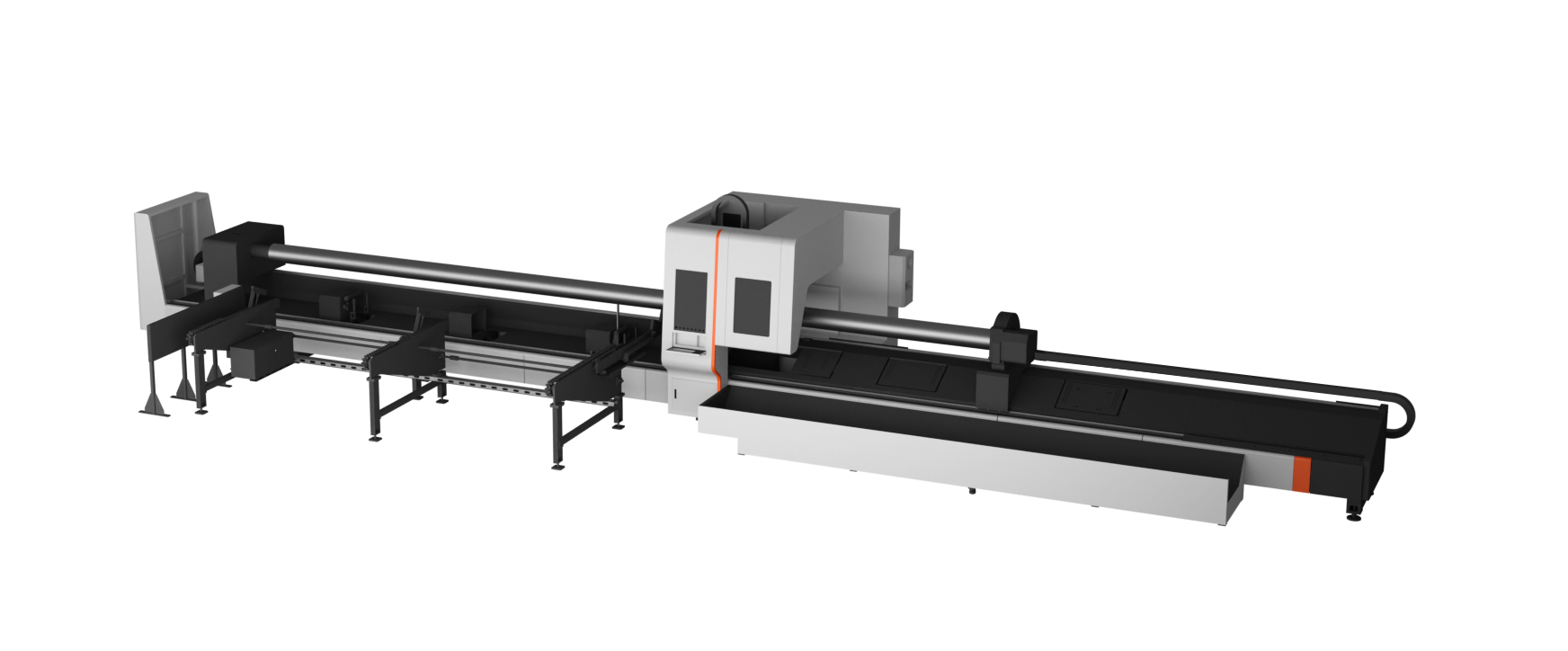

Tube laser cutting operates on the fundamental principle of directing a highly concentrated laser beam through specialized optics to create precise cuts in tubular materials. The technology utilizes fiber laser sources that generate intense light energy, which is then focused into a narrow beam capable of melting, vaporizing, or burning through metal tubes with exceptional accuracy. Advanced CNC control systems coordinate the movement of the laser head around the tube's circumference while simultaneously rotating the workpiece to achieve complex cutting patterns and geometries that would be impossible with conventional cutting methods.

The cutting process involves several critical components working in harmony to deliver superior results. High-pressure assist gases, typically nitrogen or oxygen, are delivered through specialized nozzles to blow away molten material and maintain cut quality. Modern tube laser cutting systems incorporate automatic loading and unloading mechanisms, reducing manual handling and improving overall production efficiency. The precision achievable with this technology often eliminates the need for secondary machining operations, resulting in significant time and cost savings for manufacturers.

Material Compatibility and Specifications

Contemporary tube laser cutting systems demonstrate remarkable versatility in processing various materials and tube dimensions. Steel tubes ranging from thin-walled architectural applications to heavy-duty structural components can be processed with equal precision. Stainless steel, aluminum, brass, and other non-ferrous materials respond exceptionally well to laser cutting, maintaining clean edges and minimal heat-affected zones. The technology accommodates tube diameters from as small as 6mm up to 220mm or larger, depending on the specific equipment configuration and manufacturer requirements.

Wall thickness capabilities vary based on material type and laser power specifications, with most industrial systems handling steel tubes up to 12mm wall thickness effectively. The consistent quality achieved across different materials makes tube laser cutting particularly valuable for manufacturers working with diverse material specifications or those requiring frequent material changes in their production processes. Advanced systems can automatically adjust cutting parameters based on material type and thickness, ensuring optimal results without extensive operator intervention.

Production Volume Considerations

High-Volume Manufacturing Benefits

Manufacturers operating high-volume production lines find tube laser cutting technology particularly advantageous due to its exceptional processing speeds and automation capabilities. Modern systems can process hundreds of tubes per hour, depending on complexity and material specifications, making them ideal for automotive, furniture, and construction industries where large quantities of processed tubes are required daily. The automated loading, cutting, and unloading cycles minimize labor requirements while maintaining consistent quality standards throughout extended production runs.

The technology's ability to perform multiple operations in a single setup significantly reduces production time compared to traditional methods requiring multiple machine transfers. Complex tube profiles involving holes, slots, notches, and end preparations can be completed in one continuous operation, eliminating intermediate handling and reducing the risk of dimensional variations. This comprehensive processing capability makes tube laser cutting systems highly efficient for manufacturers focused on maximizing throughput while maintaining quality standards.

Low to Medium Volume Applications

Even manufacturers with lower production volumes can benefit significantly from tube laser cutting technology, particularly when product complexity or precision requirements justify the investment. The rapid setup capabilities and flexible programming allow for efficient processing of small batches or prototype development without the extensive tooling requirements associated with conventional cutting methods. Quick changeovers between different tube sizes and cutting patterns make the technology suitable for custom fabrication shops and manufacturers serving diverse market segments.

The elimination of dedicated tooling for each cutting operation provides substantial cost savings for low-volume applications where traditional tooling costs might be prohibitive. Programming flexibility allows manufacturers to easily modify cutting patterns, accommodate design changes, or introduce new products without significant preparation time or additional equipment investments. This adaptability makes tube laser cutting systems valuable assets for manufacturers prioritizing flexibility and responsiveness to customer requirements.

Quality and Precision Requirements

Dimensional Accuracy Standards

Industries requiring exceptional dimensional accuracy find tube laser cutting technology indispensable for meeting stringent quality standards. The technology consistently achieves tolerances within ±0.1mm or better, depending on material and geometry specifications. This precision level is particularly crucial in aerospace, medical device manufacturing, and precision machinery applications where component fit and function depend on exact dimensional conformity. The laser's narrow kerf width and minimal heat input preserve material integrity while delivering clean, straight cuts with excellent edge quality.

Advanced positioning systems and real-time monitoring capabilities ensure consistent accuracy throughout the cutting process, regardless of tube length or complexity. The absence of mechanical cutting forces eliminates material distortion common with conventional cutting methods, particularly important when processing thin-walled tubes or materials prone to deformation. Automated measurement and quality control systems integrated into modern tube laser cutting equipment provide immediate feedback on dimensional accuracy, enabling real-time adjustments and maintaining quality standards throughout production runs.

Surface Finish and Edge Quality

The superior edge quality achieved through tube laser cutting often eliminates secondary finishing operations, reducing overall production costs and cycle times. Laser-cut edges typically exhibit minimal burr formation and smooth surface finishes that meet or exceed requirements for many applications without additional processing. The controlled heat input and precise beam characteristics result in narrow heat-affected zones, preserving material properties adjacent to the cut edge and maintaining structural integrity in critical applications.

Consistent cut quality across varying material thicknesses and tube geometries makes tube laser cutting particularly valuable for manufacturers serving industries with strict surface finish requirements. The technology's ability to maintain edge quality consistency throughout extended production runs ensures reliable part-to-part uniformity, critical for automated assembly processes or applications where edge condition affects subsequent operations. Advanced beam control systems can optimize cutting parameters in real-time to maintain optimal edge quality regardless of cutting speed variations or material inconsistencies.

Complex Geometry and Design Flexibility

Advanced Cutting Capabilities

Modern tube laser cutting systems excel at producing complex geometries that would be extremely difficult or impossible to achieve with conventional cutting methods. Three-dimensional cutting capabilities allow for angled cuts, intersecting holes, and complex joint preparations that eliminate extensive secondary machining operations. The technology can create precise notches, slots, and mounting features while maintaining exact positioning relationships critical for assembly operations. Advanced systems incorporate multi-axis positioning that enables cutting at various angles and orientations, expanding design possibilities for engineers and manufacturers.

The programming flexibility inherent in tube laser cutting systems allows manufacturers to implement design changes quickly without retooling or significant setup modifications. Complex nesting algorithms optimize material utilization while accommodating intricate cutting patterns, reducing waste and improving overall manufacturing efficiency. Specialized software packages enable engineers to visualize and validate cutting operations before production, minimizing errors and ensuring optimal results for complex geometries requiring precise execution.

Customization and Prototype Development

Manufacturers engaged in custom fabrication or prototype development find tube laser cutting technology invaluable for rapid iteration and design validation. The ability to quickly program and execute complex cutting patterns allows for efficient testing of design concepts without extensive tooling investments. Rapid prototyping capabilities enable manufacturers to respond quickly to customer requirements or design modifications, providing competitive advantages in markets demanding short development cycles and customized solutions.

The technology's programming flexibility supports easy modification of cutting parameters to accommodate material variations or design refinements during development phases. Engineers can experiment with different joint configurations, hole patterns, and geometric features without the time and cost penalties associated with conventional cutting methods requiring specialized tooling. This capability makes tube laser cutting systems particularly valuable for manufacturers serving markets where product customization and rapid development cycles are essential for competitive success.

Economic Factors and Investment Considerations

Cost-Effectiveness Analysis

Evaluating the economic benefits of tube laser cutting requires comprehensive analysis of both direct operational costs and indirect efficiency gains throughout the manufacturing process. While initial equipment investment may be substantial, the elimination of tooling costs, reduced labor requirements, and improved material utilization often result in attractive return on investment periods. The technology's ability to combine multiple operations into single setups reduces handling costs and minimizes work-in-process inventory, contributing to improved cash flow and reduced operational complexity.

Operating costs for tube laser cutting systems remain competitive due to high cutting speeds, minimal consumable requirements, and reduced energy consumption compared to alternative cutting methods. The precision and consistency achieved through laser cutting often eliminate costly secondary operations such as deburring, machining, or rework, further improving overall cost-effectiveness. Manufacturers should consider the cumulative impact of improved quality, reduced scrap rates, and enhanced production efficiency when evaluating the economic benefits of implementing tube laser cutting technology.

Long-Term Strategic Benefits

Beyond immediate cost considerations, tube laser cutting technology provides strategic advantages that enhance long-term competitiveness and market positioning. The capability to handle complex geometries and tight tolerances opens opportunities for manufacturers to pursue higher-value applications and premium market segments. Improved production flexibility enables manufacturers to respond more effectively to changing market demands and customer requirements without significant capital investments in additional equipment or tooling.

The technology's scalability allows manufacturers to expand production capacity efficiently as business grows, providing a foundation for sustainable long-term growth. Advanced automation capabilities reduce dependence on skilled operators while improving overall productivity and consistency, addressing labor challenges common in modern manufacturing environments. Investment in tube laser cutting technology demonstrates commitment to innovation and quality that can enhance customer confidence and support premium pricing strategies in competitive markets.

Industry-Specific Applications

Automotive and Transportation

The automotive industry represents one of the largest markets for tube laser cutting technology due to its extensive use of tubular components in vehicle structures, exhaust systems, and safety components. Modern vehicles incorporate hundreds of precisely cut tubes in chassis construction, roll cages, and structural reinforcements where dimensional accuracy and consistent quality are critical for safety and performance. The technology's ability to create complex joint preparations and mounting features eliminates expensive secondary machining operations while ensuring precise fit and optimal welding characteristics.

Exhaust system manufacturing particularly benefits from tube laser cutting capabilities, as the technology can create precisely positioned mounting brackets, sensor ports, and connection flanges while maintaining smooth internal surfaces critical for optimal flow characteristics. The clean cuts and minimal heat-affected zones preserve material properties essential for high-temperature exhaust applications. Advanced nesting capabilities optimize raw material utilization, crucial for cost-sensitive automotive applications where material costs significantly impact overall component pricing and competitiveness.

Construction and Architecture

Construction and architectural applications increasingly rely on tube laser cutting for creating custom structural components, decorative elements, and specialized building systems. The technology enables architects and engineers to implement complex designs involving intersecting tubes, custom connections, and intricate geometric patterns that enhance both structural performance and aesthetic appeal. Precise cutting capabilities ensure proper fit-up during field assembly, reducing installation time and minimizing field modifications that can compromise structural integrity.

Curtain wall systems, space frame structures, and architectural metalwork benefit significantly from tube laser cutting precision and flexibility. The ability to create precise mounting points, drainage features, and connection details ensures optimal performance and longevity in demanding outdoor environments. Custom fabrication capabilities enable manufacturers to respond effectively to unique architectural requirements while maintaining cost-effectiveness through efficient material utilization and reduced secondary processing requirements.

Quality Control and Repeatability

Process Monitoring and Validation

Advanced tube laser cutting systems incorporate sophisticated monitoring technologies that ensure consistent quality throughout production runs while providing real-time feedback on cutting performance. Integrated sensors monitor beam quality, focus position, and cutting parameters continuously, enabling automatic adjustments that maintain optimal cutting conditions regardless of material variations or environmental factors. These monitoring capabilities provide manufacturers with detailed process documentation supporting quality management systems and traceability requirements.

Automated quality control systems can perform dimensional verification and surface finish assessment immediately after cutting operations, identifying any deviations from specifications before parts proceed to subsequent manufacturing stages. Statistical process control integration enables manufacturers to track quality trends and implement preventive measures before quality issues impact production output. The combination of process monitoring and quality verification provides manufacturers with confidence in consistent part quality and supports lean manufacturing initiatives focused on waste reduction and continuous improvement.

Certification and Standards Compliance

Industries requiring strict adherence to quality standards and certification requirements find tube laser cutting technology supportive of compliance efforts through its consistent performance and comprehensive documentation capabilities. The precision and repeatability achieved through laser cutting help manufacturers meet demanding specifications in aerospace, medical device, and pressure vessel applications where component quality directly impacts safety and performance. Automated documentation systems maintain detailed records of cutting parameters, quality measurements, and process conditions supporting audit requirements and certification maintenance.

Traceability requirements common in regulated industries are well-supported by tube laser cutting systems that can maintain part-level documentation throughout the manufacturing process. Integration with enterprise resource planning systems enables comprehensive tracking from raw material receipt through final inspection and delivery. This level of documentation and process control supports manufacturers pursuing quality certifications and helps maintain compliance with evolving industry standards and regulatory requirements.

FAQ

What materials can be processed with tube laser cutting technology

Tube laser cutting systems can process a wide range of materials including carbon steel, stainless steel, aluminum, brass, copper, and various alloy compositions. The technology works effectively with tube diameters ranging from 6mm to over 220mm and wall thicknesses up to 12mm in steel materials. Different materials may require specific cutting parameters and assist gases to achieve optimal results, but modern systems can automatically adjust settings based on material type and specifications.

How does tube laser cutting compare to traditional cutting methods in terms of speed

Tube laser cutting typically operates significantly faster than traditional mechanical cutting methods, with processing speeds often 3-5 times higher depending on material thickness and complexity. The technology eliminates tool changes and reduces setup time between different cutting operations, resulting in higher overall throughput. Additionally, the ability to perform multiple operations in a single setup reduces total processing time compared to methods requiring multiple machine transfers and secondary operations.

What maintenance requirements are associated with tube laser cutting systems

Regular maintenance for tube laser cutting systems includes cleaning optical components, replacing consumable items such as nozzles and protective windows, and performing routine calibration checks. Most modern systems feature automated maintenance alerts and diagnostic capabilities that guide operators through required procedures. Preventive maintenance schedules typically involve daily, weekly, and monthly tasks that can be performed by trained operators, with more extensive service requirements handled by qualified technicians on annual or bi-annual schedules.

How quickly can manufacturers expect return on investment from tube laser cutting equipment

Return on investment periods for tube laser cutting equipment typically range from 1-3 years depending on production volume, application complexity, and current manufacturing methods being replaced. Factors contributing to ROI include reduced labor costs, elimination of secondary operations, improved material utilization, and enhanced production capacity. Manufacturers processing high volumes of complex parts or those requiring exceptional precision often experience shorter payback periods due to the significant operational improvements achieved through laser cutting technology.

Table of Contents

- Understanding Tube Laser Cutting Technology

- Production Volume Considerations

- Quality and Precision Requirements

- Complex Geometry and Design Flexibility

- Economic Factors and Investment Considerations

- Industry-Specific Applications

- Quality Control and Repeatability

-

FAQ

- What materials can be processed with tube laser cutting technology

- How does tube laser cutting compare to traditional cutting methods in terms of speed

- What maintenance requirements are associated with tube laser cutting systems

- How quickly can manufacturers expect return on investment from tube laser cutting equipment