Beyond Metal: Fiber Laser Cutting in Aerospace & Automotive Composites

Meta Description: Pushing the boundaries of manufacturing. Learn how high-brightness fiber lasers enable zero-taper, carbon-free cutting of advanced composites like CFRP and GFRP for aerospace and automotive industries.

Introduction

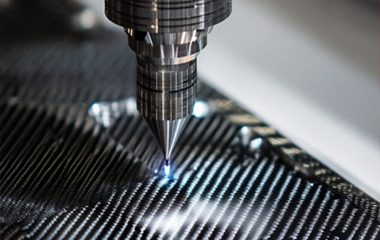

The demand for lightweight, high-strength materials is skyrocketing, especially in the aerospace and automotive sectors. Advanced composites like Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) are at the forefront of this trend. However, traditional cutting methods often fail, causing delamination, tool wear, and thermal damage. Enter high-brightness fiber laser technology—the precise, clean solution for these challenging materials.

The Challenge of Cutting Composites

Conventional machining (routing, drilling) causes fraying and delamination, where the layers of the composite separate, weakening the structure. Abrasive water jets can introduce moisture and have high operating costs. Standard lasers often create a large Heat-Affected Zone (HAZ), burning the polymer matrix and leaving a charred, weakened edge. This is unacceptable for critical components like aircraft fuselage panels or automotive chassis parts.

How High-Brightness Fiber Lasers Solve This

Modern fiber lasers have overcome these limitations through precision and control:

Ultra-High Beam Quality (Low BPP): This allows the laser energy to be focused into an extremely small spot, concentrating heat input.

Zero-Taper Cutting: With optimized parameters, the laser can cut vertically through the material, producing near-perfect 90-degree edges (ΔT≈0), which is vital for perfect part fit and assembly.

Elimination of Carbonization (Charring): The process can be tuned to vaporize the polymer matrix instantly before it has time to burn, leaving a clean, resin-free edge that maintains the composite's structural integrity.

Real-World Applications and Benefits

Aerospace: Cutting CFRP components for interior panels, brackets, and ducting with absolute precision, ensuring they meet strict weight and safety standards.

Automotive: Profiling GFRP body panels and cutting battery trays for electric vehicles (EVs) without any risk of short-circuiting from carbon dust. This eliminates post-process cleaning, boosting production line efficiency and yield.

Conclusion: Enabling the Future of Lightweighting

Fiber laser cutting is no longer just for metals. It has become an enabling technology for the lightweight revolution in aerospace and automotive manufacturing. By providing a clean, fast, and automated method for processing advanced composites, it allows engineers to design with these materials confidently, pushing the boundaries of performance and efficiency.