Modern manufacturing demands precision, speed, and versatility in metal fabrication processes. Among the most revolutionary technologies transforming industrial production today, tube laser cutting stands out as a game-changing solution for creating complex profiles and intricate cuts in tubular materials. This advanced manufacturing technique combines the power of fiber laser technology with sophisticated automation systems to deliver unparalleled accuracy and efficiency in processing various tube geometries. Understanding how to select the optimal tube laser cutting equipment requires careful consideration of multiple technical and operational factors that directly impact production capabilities and long-term profitability.

Understanding Tube Laser Cutting Technology Fundamentals

Core Technology Components and Operating Principles

Tube laser cutting technology operates on the principle of focused laser beam energy that melts, vaporizes, or burns through material along predetermined cutting paths. The system integrates a high-power fiber laser source with precision beam delivery optics, automated material handling systems, and sophisticated control software. Unlike traditional mechanical cutting methods, tube laser cutting achieves remarkable precision without physical tool contact, eliminating concerns about tool wear and maintaining consistent cut quality throughout extended production runs.

The laser beam generation process begins with diode pumping of rare-earth-doped fiber cores, creating coherent light that gets amplified and focused to extremely high power densities. Advanced beam shaping optics ensure optimal energy distribution across the cutting zone, while assist gas systems remove molten material and prevent oxidation during the cutting process. Modern tube laser cutting systems incorporate real-time monitoring capabilities that adjust cutting parameters dynamically based on material feedback and geometric requirements.

Material Processing Capabilities and Limitations

Contemporary tube laser cutting equipment demonstrates exceptional versatility across diverse material types and thicknesses. Carbon steel, stainless steel, aluminum alloys, brass, copper, and various exotic metals can be processed with remarkable precision and edge quality. The technology excels particularly in processing thin to medium-thickness materials, typically ranging from 0.5mm to 25mm depending on material type and laser power specifications.

Different materials require specific cutting parameters and assist gas combinations to achieve optimal results. Carbon steel benefits from oxygen-assisted cutting for thick sections, while nitrogen assist gas produces superior edge quality in stainless steel applications. Aluminum and copper present unique challenges due to their high reflectivity and thermal conductivity, requiring specialized cutting techniques and enhanced laser power management. Understanding these material-specific requirements becomes crucial when selecting tube laser cutting systems for specific manufacturing applications.

Critical Selection Criteria for Tube Laser Systems

Laser Power Requirements and Performance Specifications

Determining appropriate laser power represents one of the most fundamental decisions in tube laser cutting equipment selection. Power requirements directly correlate with material thickness capabilities, cutting speed potential, and overall system productivity. Lower power systems typically range from 1kW to 3kW, suitable for thin materials and precision applications, while high-power systems exceed 6kW for heavy-duty industrial production environments.

Cutting speed capabilities vary significantly based on laser power, material type, and required edge quality standards. Higher power systems achieve faster traverse rates but may require more sophisticated cooling systems and increased operational costs. The relationship between laser power and cutting quality follows complex curves that depend on material properties, thickness, and specific application requirements. Evaluating these performance characteristics against production volume expectations ensures optimal system sizing and cost-effectiveness.

Tube Geometry Compatibility and Processing Range

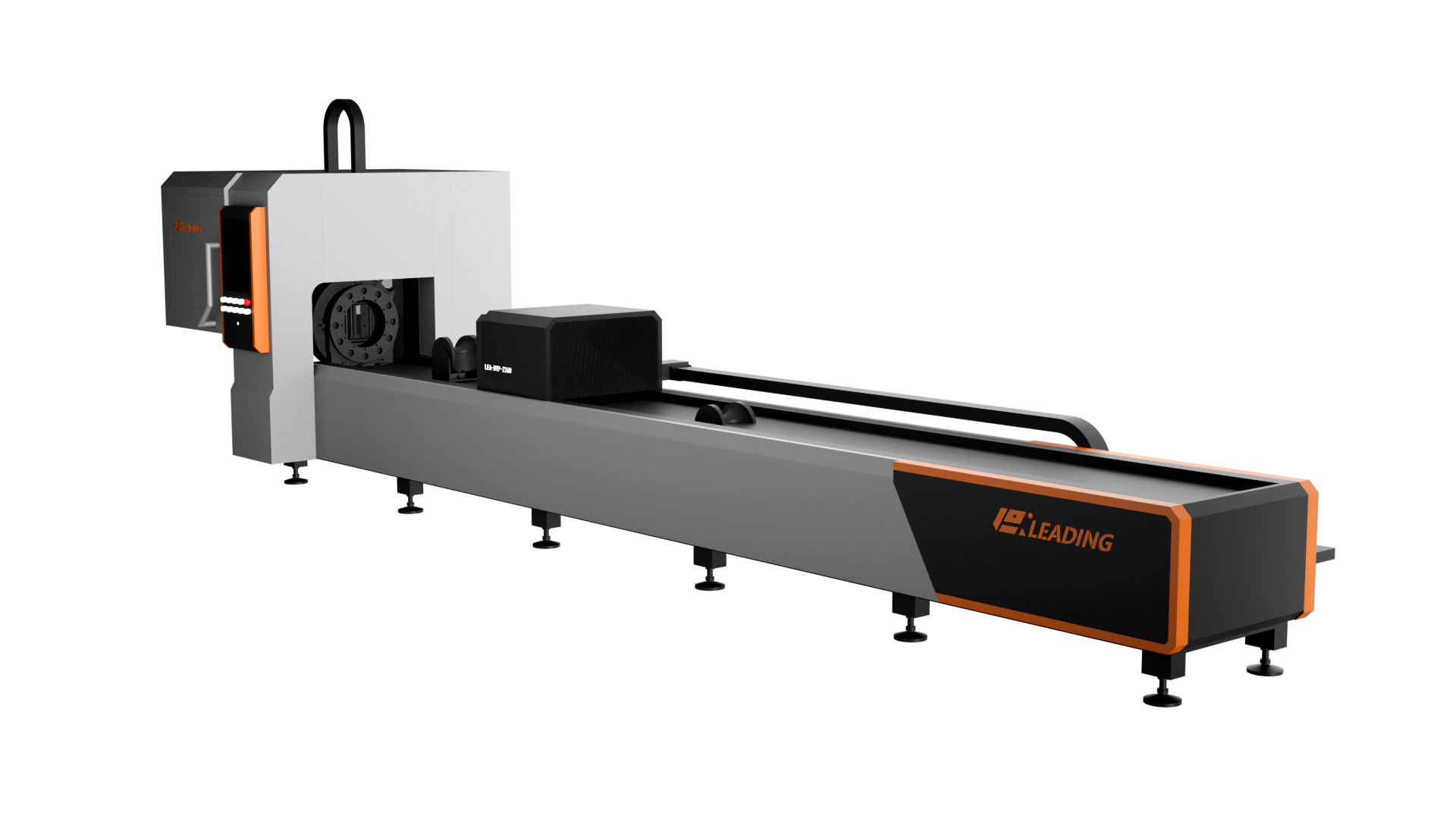

Modern tube laser cutting systems accommodate diverse geometric profiles including round tubes, square sections, rectangular profiles, and complex custom shapes. Maximum tube diameter capabilities typically range from 6mm to 300mm or larger, while length processing capabilities can extend several meters depending on system configuration. Understanding the full range of geometric requirements for current and future production needs prevents costly limitations and ensures long-term system viability.

Wall thickness processing capabilities represent another critical consideration that impacts material utilization efficiency and production flexibility. Minimum wall thickness limitations often determine system suitability for precision applications, while maximum thickness capabilities define heavy-duty processing potential. Advanced tube laser cutting systems incorporate automatic tube rotation and positioning mechanisms that enable complex multi-angle cuts and intricate profile modifications without manual intervention.

Production Environment and Integration Considerations

Automation Level and Material Handling Systems

The degree of automation significantly influences tube laser cutting system productivity and operational efficiency. Basic systems require manual tube loading and positioning, suitable for small batch production or prototyping applications. Semi-automatic systems incorporate powered tube rotation and automated cutting head positioning, reducing operator intervention while maintaining production flexibility. Fully automatic systems integrate conveyor systems, automatic loading mechanisms, and sophisticated part sorting capabilities for high-volume manufacturing environments.

Material handling automation extends beyond basic loading and unloading functions to include tube identification, quality inspection, and integrated inventory management systems. Advanced tube laser cutting installations incorporate barcode scanning, automatic measurement verification, and real-time production tracking capabilities. These automation features reduce labor requirements, minimize handling errors, and provide comprehensive production documentation for quality control and traceability purposes.

Software Integration and Programming Capabilities

Sophisticated software systems form the backbone of modern tube laser cutting operations, providing intuitive programming interfaces and advanced optimization algorithms. CAD/CAM integration capabilities enable direct import of engineering drawings and automatic tool path generation, significantly reducing programming time and potential errors. Nesting optimization software maximizes material utilization by automatically arranging multiple parts within available tube lengths while considering cutting sequence optimization.

Real-time process monitoring and adaptive control systems represent cutting-edge developments in tube laser cutting technology. These systems continuously analyze cutting performance parameters and automatically adjust laser power, cutting speed, and assist gas flow rates to maintain optimal cut quality. Advanced predictive maintenance algorithms monitor system component performance and provide early warning indicators for scheduled maintenance activities, minimizing unplanned downtime and extending equipment lifespan.

Economic Analysis and Return on Investment

Initial Capital Investment and Financing Considerations

Tube laser cutting equipment represents significant capital investments that require careful financial planning and justification analysis. Entry-level systems typically start around several hundred thousand dollars, while high-end automated installations can exceed several million dollars depending on configuration and capabilities. Understanding the complete cost structure including installation, training, and initial tooling helps establish realistic budget parameters and financing requirements.

Equipment financing options include traditional capital purchases, lease agreements, and innovative pay-per-use models that align equipment costs with production output. Lease arrangements provide immediate access to advanced tube laser cutting technology without large upfront investments, while purchase options offer long-term ownership benefits and potential tax advantages. Evaluating different financing structures against projected production volumes and revenue streams ensures optimal financial alignment with business objectives.

Operational Cost Analysis and Productivity Metrics

Comprehensive operational cost analysis encompasses electricity consumption, consumable materials, maintenance expenses, and labor requirements. Fiber laser technology typically demonstrates superior electrical efficiency compared to traditional CO2 laser systems, reducing ongoing power costs. Consumable expenses include cutting gases, protective lenses, nozzles, and periodic maintenance items that require regular replacement based on production volume and operating conditions.

Productivity metrics for tube laser cutting systems include cutting speed, material utilization efficiency, setup time requirements, and overall equipment effectiveness measurements. Advanced systems achieve remarkable productivity gains through reduced setup times, automated material handling, and optimized cutting sequences. Comparing these productivity metrics against current manufacturing methods provides quantitative justification for equipment investments and establishes performance benchmarks for operational success.

Vendor Selection and Support Considerations

Manufacturer Reputation and Technical Support

Selecting reputable tube laser cutting equipment manufacturers ensures access to proven technology, comprehensive support services, and long-term system reliability. Established manufacturers typically offer extensive application engineering support, comprehensive training programs, and responsive technical service organizations. Evaluating manufacturer track records, customer references, and installed base statistics provides valuable insights into system performance and support quality expectations.

Technical support capabilities extend beyond basic troubleshooting to include application development, process optimization, and continuous improvement initiatives. Leading manufacturers provide remote diagnostic capabilities, online training resources, and proactive maintenance programs that maximize system uptime and performance. Understanding available support levels and response time commitments helps establish realistic expectations for ongoing operational support and maintenance requirements.

Training Programs and Knowledge Transfer

Comprehensive operator training programs ensure successful tube laser cutting system implementation and optimal performance achievement. Effective training covers safety procedures, basic operation, programming techniques, and routine maintenance activities. Advanced training modules include troubleshooting methodologies, process optimization techniques, and specialized application development for complex manufacturing requirements.

Knowledge transfer extends beyond initial training to include ongoing education and skill development programs. Leading equipment suppliers offer continuing education opportunities, user conferences, and technical seminars that keep operators current with evolving tube laser cutting technologies and best practices. Investing in comprehensive training and knowledge development maximizes equipment utilization and ensures long-term operational success.

FAQ

What factors determine the appropriate laser power for tube laser cutting applications?

Laser power selection depends primarily on maximum material thickness requirements, desired cutting speeds, and production volume expectations. Thicker materials require higher laser powers to achieve acceptable cut quality and productivity levels. Generally, 1-3kW systems handle materials up to 6mm effectively, while 4-6kW systems process materials up to 15mm thickness. Higher power systems above 8kW enable processing of materials exceeding 20mm thickness with superior cutting speeds and edge quality.

How does tube geometry complexity affect equipment selection and capabilities?

Complex tube geometries including square, rectangular, and custom profiles require advanced chuck systems and rotational capabilities to maintain proper positioning during cutting operations. Multi-axis tube laser cutting systems provide enhanced flexibility for processing complex shapes and enabling bevel cuts, while simpler systems may be limited to basic round tube applications. The maximum tube diameter and length capabilities must align with specific production requirements to ensure adequate processing range and flexibility.

What maintenance requirements should be considered for tube laser cutting systems?

Regular maintenance includes laser source servicing, optical component cleaning, assist gas system maintenance, and mechanical component lubrication. Fiber laser sources typically require minimal maintenance with service intervals ranging from 20,000 to 100,000 hours depending on operating conditions. Consumable replacement includes cutting nozzles, protective lenses, and assist gas filters based on production volume. Preventive maintenance schedules should be established based on manufacturer recommendations and actual operating experience.

How do material handling requirements influence tube laser cutting system selection?

Material handling requirements directly impact automation level selection and overall system configuration. Manual systems suit low-volume applications with frequent part changes, while automatic loading systems optimize high-volume production efficiency. Tube length capabilities, weight handling capacity, and part sorting requirements must be evaluated against production needs. Integration with existing material handling infrastructure and workflow patterns influences system layout and automation level decisions significantly.

Table of Contents

- Understanding Tube Laser Cutting Technology Fundamentals

- Critical Selection Criteria for Tube Laser Systems

- Production Environment and Integration Considerations

- Economic Analysis and Return on Investment

- Vendor Selection and Support Considerations

-

FAQ

- What factors determine the appropriate laser power for tube laser cutting applications?

- How does tube geometry complexity affect equipment selection and capabilities?

- What maintenance requirements should be considered for tube laser cutting systems?

- How do material handling requirements influence tube laser cutting system selection?